4 ABUS EOT cranes at a world-renowned Spanish ship building company

Machines in the shipbuilding industry – working under the toughest conditions

In the far northwest of Spain you will find Cape Finisterre, so called after the Latin Finis terrae which means “the End of the World”. A long time ago one used to think that here on the shores of the rough Atlantic ocean the world had come to an end. A little further south, close to the Portuguese border, you will then come across the town of Vigo. To this day Vigo is one of the most important ports in Spain and a historical site for dockyards. The region around Vigo has always given birth to extraordinary shipbuilders and as such is an ideal place to marry the experience of fishermen with the high technical qualifications of the shipbuilding engineers. Today there are these highly specialised companies in particular that have secured their position in this very demanding sector of the market which is much fought over. Most exacting demands are made on ships, equipment, and materials and all have to prove their worth, i.e. their resistance and their reliability, while working under the toughest conditions.

IBERCISA – the highest duty is quality

One of the leading companies in the shipbuilding industry is the Spanish company IBERCISA (www.ibercisa.es) in Vigo. The company was founded in 1969 and, at first, was only producing components for fishing boats. In the course of the years IBERCISA enlarged their production programme and their worldwide presence: today IBERCISA are exporting goods to more than 45 countries and at their site in Vigo they produce towing winches, rope and anchor winches, rope drums and other mooring and rigging fixtures. These components are going to be used on fishing vessels, on merchant and naval ships, and also on scientific research vessels. For their production IBERCISA rely on staff highly qualified in welding techniques and processing technology but also on corresponding machinery including several machining centres and milling machines, as well as boring and flame cutting machines. The cranes in the production halls are also part of this machine park at the same time guarantying safe material flow. When IBERCISA were going to enlarge their production they quickly decided on ABUS as a reliable supplier of crane systems.

ABUS cranes to meet new transport requirements

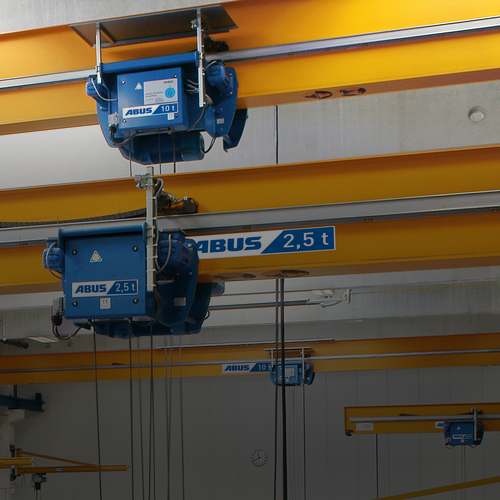

Four EOT cranes were installed in total in order to assure material flowing through the new IBERCISA production halls. Three cranes have a span of 12.37 metres and the forth, installed in neighbouring building, has a span of 9.3 metres. The biggest crane is a double girder crane ZLK with a load capacity of 80 / 10 tonnes. This crane features two hoists, i.e. one double rail trolley with twin hoist GM7000 and another double rail trolley GM3000 of the D type. The smaller hoist is used for the majority of the lifting operations as the load to be lifted does not normally exceed ten tonnes. The wire rope hoist with a lifting capacity of 80 tonnes is used as and when needed, normally to move fully assembled units.

The second EOT crane is also a double girder crane, however the load capacity is smaller: SWL is 20 tonnes. The third crane is a single girder crane ELK with a load capacity of 10 tonnes and a single rail trolley GM3000 of the E type. All three cranes feature photo-electronic anti-collision devices and are controlled via radio remote control. The fourth crane is also a single girder crane of the Elk type but with a load capacity of 10 tonnes. This crane features also a wire rope hoist type E but is characterised by a special main girder connection version: the main girder is stooled-up for maximum use of the height of the building. IBERCISA use all cranes in different phases of the assembly of the ship building components.

ABUS Gruas (www.abusgruas.es), the Spanish daughter company of ABUS Kransysteme GmbH, was responsible not only for the installation of the cranes and the power supplies in this project but also had the supervision of the construction and the installation of the steel structures. For IBERCISA ABUS Grúas is a supplier committed to quality and customer satisfaction exactly as they are.