OVERHEAD TRAVELLING CRANES

ABUS overhead travelling cranes lift loads of up to 120 t making them the ideal solution for particularly demanding tasks and large spans.

Single girder overhead travelling crane

ABUS single girder travelling cranes guarantee optimal material flow even in situations where space is at a premium as in production plants or warehouses where there is little room for crane systems. ABUS single girder travelling cranes are available with rolled section girders or with welded box girders. Thanks to different main girder connection versions, each type of crane can be optimised to minimise headroom and achieve the highest possible hook position.

Product details Price enquiryDouble girder overhead travelling crane

ABUS double girder overhead travelling cranes achieve the maximum load capacity of up to 120 tonnes. They are available in various configurations and feature the versatility required for additional requirements. It is very easy to implement higher crane travel speeds, service platforms, trolleys with walkways, and auxiliary hoists for example.

Product details Price enquiryUnderslung overhead travelling crane

ABUS underslung overhead travelling cranes offer solutions in applications where gantry tracks are fitted to ceilings rather than free-standing or building columns. Optimal side approach dimensions make it possible to use the maximum available building width.

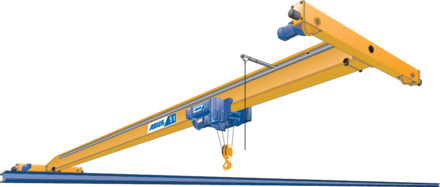

Product details Price enquirySingle girder wall travelling crane

ABUS wall travelling cranes travel on their own crane tracks at building mid-level beneath high-level overhead travelling cranes. They are an ideal solution for covering several workstations with a single installation. ABUS wall travelling cranes type EWL reach spans of up to 12 m and have load capacities of up to 5 t.

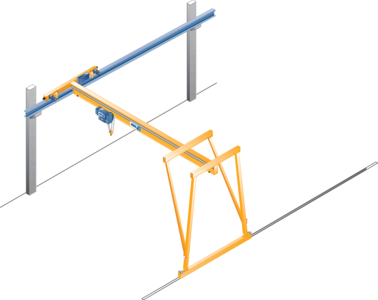

Product details Price enquirySingle girder semi-goliath crane

The ABUS single girder semi-goliath crane EHPK is particularly suited to the movement of goods of up to 10t at mid-level. The EHPK also integrates smoothly into existing material flow systems: the upper end carriage travels on normal crane tracks and the lower end carriage does not require guide rails thus being free from any edges or hazards. Loading on the building structure is minor. A combination of obstacle recognition and rotating beacon make sure the semi-goliath crane is operated safely. From the economic point of view this crane is characterised by comparatively low investment costs and can be installed easily and quickly.

Product details Price enquiryFAQ

There are some common mistakes when selecting an overhead crane that can be avoided if the application and its specific requirements are carefully considered. One common mistake is an unclear definition of technical requirements such as load capacity, lifting height or span. A thorough needs analysis that also takes into account possible future-proofing helps here.

The environment in which the crane is used is also often underestimated. Temperature, humidity, dust and possible chemicals in the air can have a significant impact on the service life and performance of the crane. A crane used in an environment with extreme temperatures or high dust levels requires more robust materials and additional protective measures. Another point is the choice of control: if it is not suitable for the working environment, efficiency will suffer. In areas that are difficult to access or in harsh ambient conditions, radio remote control is often the better choice to ensure safe and precise movements.

Another common mistake is choosing the wrong load capacity: a crane that is overspecified causes unnecessarily high costs, while a crane that is underspecified carries the risk of overload. It is therefore essential to determine a realistic load capacity with an appropriate safety margin. The spatial conditions are also often neglected. The crane must fit into the building and have sufficient room to manoeuvre to be able to work safely and effectively – an early check of the spatial conditions is therefore necessary.

Maintenance is also often neglected. A crane that is difficult to access or requires special spare parts makes maintenance more difficult and can lead to long downtimes. Therefore, maintenance-friendly cranes and good availability of service and spare parts are also important selection criteria.

Taking these factors into account – the technical requirements as well as the environment and maintenance – can help to avoid expensive mistakes, increase safety and ensure the long-term cost-effectiveness of the crane. An ABUS advisor will help you to make the right choice and avoid mistakes.

A jib crane is attached to the floor of the building or to a wall bracket and can only move loads in a circular or semi-circular swept area. An overhead crane can move loads freely in all three dimensions throughout the entire building without taking up valuable space on the floor. This makes it easier to move materials around the building. If you're not sure whether an overhead travelling crane is the better choice, you can get expert advice from an ABUS advisor.

Basically, the load capacity of a crane is the maximum load it can lift. There are two things to think about here: Cranes are a long-term investment. The way things are used can change over time, so if you're not sure, pick a higher load capacity than you need now. You can increase the capacity in most cases, but it'll always be a bit of a hassle.

And don't forget that the necessary lifting gear is also part of the load capacity. You can't always hang a load straight on the hook, so you need a crosshead, which can sometimes add a lot of dead weight.

Once you know the max load, you can look at the different types of cranes and hoists, which are based on standardised number series like the Renard series (DIN 323 / ISO 3).

80 kg

100 kg

125 kg

160 kg

200 kg

250 kg

320 kg

400 kg

500 kg

630 kg

800 kg

1.0 t

1.25 t

1.6 t

2.0 t

...

Once you know the required load capacity of the crane and the hall statics are big enough for the dead weight of the crane, hoist and attached load, you can get more details from an ABUS advisor.

Overhead traveling cranes (like bridge or gantry cranes) are used in all sorts of industries, logistics, and construction. They're great for moving heavy loads efficiently, safely, and precisely. They're a must-have, especially in big production facilities, warehouses, and heavy industrial plants. There's a ton of different ways to use this stuff, and they're all related to the industrial sector. Here are a few examples:

- Manufacturing and mechanical engineering, especially in the automotive industry and steelworks.

- Warehouses and logistics centers of all kinds—like high-bay warehouses and container transhipment centers.

- There's a lot going on in construction right now. For example, there are concrete pre-casting plants, bridge construction, and wind turbine construction.

- Metal processing and foundry work.

- Shipbuilding and power plants

- Recycling and Disposal

If you're trying to decide between a light crane system or a jib crane versus an overhead traveling crane, you can talk about it with an ABUS advisor.

Our overhead travelling cranes for your area of application

The overhead travelling cranes from ABUS can be perfectly adapted to your areas of application and operational requirements. You will find different designs such as single girder and double girder overhead travelling cranes, underslung travelling cranes, single girder wall travelling cranes and single girder semi-goliath cranes.

Make ideal use of available space – this works best with an overhead travelling crane. This overhead travelling crane enables an excellent use of space even in low buildings and achieves optimum lifting heights thanks to its favourable dimensions. This indoor crane offers safe working load capacities of up to 16 t and spans of up to 39 m.

A double girder overhead travelling crane is ideal for lifting and moving particularly heavy loads of up to 120 t. It impresses with a large span of up to 40 m and can be equipped with additional features depending on the requirements, such as maintenance walkways on the crane bridges, a crab unit with a maintenance platform or with an additional hoist. Therefore, a crab unit with a maintenance platform and a maintenance walkway on the crane bridge provide significant advantages when carrying out maintenance work.

Even buildings without preparation for a runway beam (e.g. non-load-bearing building supports) can be equipped with an overhead travelling crane. An underslung travelling crane is exactly the right thing for such building conditions. The runway beams are mounted directly under the ceiling without the need for any additional supports, making ideal use of available space. The underslung travelling cranes offer load capacities of up to 8 t and spans of up to 17.5 m.

A single girder wall travelling crane is usually installed below a larger overhead travelling crane, i.e. at the mid-level of the building. In perfect interaction with the travelling overhead travelling crane above, the single girder wall travelling crane travels along the building wall and thus serves several workplaces at the same time. The single girder wall travelling crane can achieve a maximum load capacity of up to 5 t and a maximum jib length of 12 m (SWL dependent).

Our single girder semi-goliath crane also travels at the mid-level of the building and can serve multiple workplaces in a production line. If the building floor is even and has a sufficient load-bearing capacity, the lower end carriage can be moved directly on it using a flat wheel – consequently removing the need for a low-level guide rail, which would cause an obstacle. Our ABUS single girder semi-goliath cranes have maximum load capacity of 10 t and a span of up to 15 m (SWL dependent).

Overhead travelling cranes from ABUS

ABUS is one of the major manufacturers of standard indoor cranes in Europe – and we offer you an all-round service. We develop customized solutions for economical material flow, assist with the planning, maintenance and repair of your crane installations and are at your disposal with our professional services at any time.

Thanks to the various installation options, our cranes can be ideally integrated into the planning for a new building or for installation into an existing building and guarantee maximum flexibility, functionality and ideal operating characteristics.

No crane travel without runway beam

We can also offer you a customized solution for the required runway beam, depending on your project requirements or existing building support structure. Our team of engineers supports you competently in all planning phases. In this way, we provide you a complete solution comprising crane and runway beam – everything from one source.

Additional equipment and options

Our innovative ABUS radio control ‘ABURemote’ with inductive charging cradle is a useful piece of additional equipment available for every ABUS overhead travelling crane. With our ABURemote radio control you are independent – You are free to choose the location from which you want to operate the overhead travelling crane and therefore will always have the best view of the complete working area. The ABURemote radio control has numerous functions and options, for example, a tandem control system for two overhead travelling cranes with two hoists on each crane. In combination with our modern control system ABUControl, the handling of long products is not only safe but also child’s play thanks to our synchronization and sway controls.

Additional equipment for overhead travelling cranes such as highly-efficient LED lights that optimally illuminate the working area of the cranes and a calibratable (also retrofittable) weighing bottom block are two examples of further ABUS options in crane construction that enhance operation. Everything for the safety and operating comfort of your employees. Put together your own overhead cranes and completely individual crane systems using our many additional options!

Your crane installation from ABUS Crane Systems

Let a competent ABUS contact advise you on your project about overhead cranes or other crane systems. We accompany you from the planning stage through installation (by request, including installation equipment such as mobile cranes, fork lifts or aerial work platform) to testing and commissioning before initial operation. We would be pleased to support you in the efficient planning & design of your facility through multiple working levels. For this purpose, our crane technology offers you further solutions such as a slewing jib crane (pillar jib cranes, wall-mounted jib cranes), our lightweight mobile gantry (LPK) or our suspended HB monorail or light crane systems. It goes without saying that we also offer you suitable hoists such as electric chain hoists or electric wire rope hoists. We will advise you which crane option is suitable for your project and would be pleased to offer the manufacture of new systems or consider the modernization of existing crane systems. Please contact us!