Cranes

Cranes for light and heavy transport

In almost all manufacturing or production environments, logistical tasks need to be solved. ABUS cranes are the optimum solution for your company and all kind of building situations, even at different working levels. With our standard cranes, we offer you complete solutions for your working process – with a load capacity range from 80 kg to 120 t.

Overhead travelling cranes

ABUS overhead travelling cranes lift loads of up to 120 tonnes.

Product detailsHB-systems

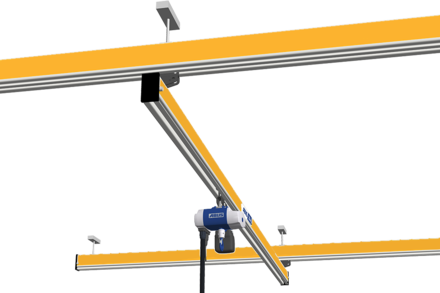

ABUS HB Systems are synonymous with flexible and reliable materials handling solutions.

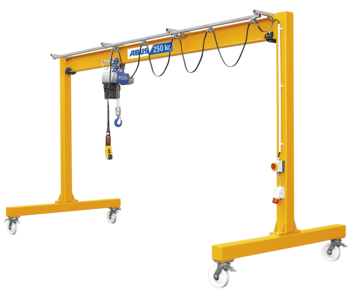

Product detailsLightweight mobile gantry

ABUS lightweight mobile gantry cranes give your chain hoists mobility.

Product detailsFAQ

In addition to the purchase price of an indoor crane, other costs may arise that need to be taken into account when planning and budgeting. These include transport costs, which can vary greatly depending on the travel distance as well as the size and weight of the crane components. These costs can increase particularly for large crane systems or difficult site conditions. Installation variables should also be considered as installing the crane, potential gantry fitting, control system set up and any on-site adjustments can all incur additional costs.

Other important points are the planning and static calculations required to ensure that the supporting structure can support the crane loads. This may require externalconsultant advice with its associated costs. Likewise, additional equipment such as special hoists, automation technology or additional safety devices can increase the overall costs.

In addition, service and maintenance contracts are a factor to consider. Regular maintenance is essential to maximise the lifespan of the crane and ensure safe operation. These maintenance services incur ongoing costs, but can minimise repairs and downtime in the long term. Training for operating personnel is also important to ensure safe and efficient use of the crane. These training courses may incur additional costs, depending on the provider and whether the course is certificated.

Depending on the location and size of the crane, official permits such as police escorts may also be required, for which further fees will be incurred. Finally, insurance costs may be incurred to cover the crane against damage or breakdown. The amount of these costs depends on the type and value of the crane, as well as on the conditions of use.

To avoid any nasty surprises, these additional costs should be included at the outline planning stage. Comprehensive advice can help to identify all possible additional costs and to create a realistic budget.

ABUS cranes aren't usually made for outdoor use. But there are times when you can use overhead cranes to move stuff around in outdoor areas, even if they're not fully up and running. This means you'll need to make some extra adjustments, like adding corrosion protection and weatherproof parts, or a heating system for the gearbox oil. Wind can be a real problem, which is why cranes are only operated up to a certain wind speed.

It's got a wind measuring system that notifies you when a certain wind speed is reached. Then, the crane has to be moved within a certain time to its park position at the gantry end or back into a building, or it needs to be mechanically anchored. It's a good idea to chat with an ABUS advisor about the specific operating conditions to make sure the crane is suitable for the job.

ABUS Crane Systems offers a variety of crane systems that are tailored to different requirements and applications. These include:

1. Overhead travelling cranes: Overhead travelling cranes sometimes known as gantry cranes or bridge cranes are ideal for large buildings and offer high load capacity and flexibility of movement.

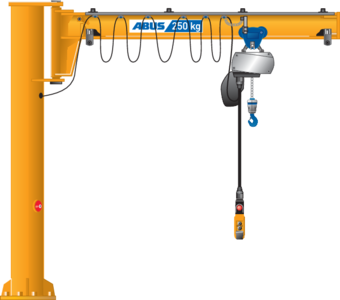

2. Jib cranes: These are ideal for smaller operating ranges and allow for easy handling of loads within a limited radius.

3. Light crane systems: These allow for overhead material transport over longer distances and are ideal for production or logistics facilities.

4. Mobile gantry cranes: These crane systems are particularly mobile and are well suited for use in workshops or in large warehouses.

5. Wire rope and chain hoists: These components are used as lifting gear in crane systems and make it easy to lift and lower loads.

In addition to the daily inspection of the wire ropes by the crane operator, ABUS cranes should be regularly serviced to ensure their safety, performance and durability. As a rule, annual maintenance is required, which can also be carried out more frequently depending on the frequency and intensity of use. In the case of intensive use or special operating conditions, e.g. three-shift operation, it may be advisable to carry out maintenance more frequently, e.g. every four or six months.

Maintenance includes a comprehensive inspection of all safety-related components, such as mechanical and electronic components and safety devices. This includes estimating the remaining service life and checking the control system, brakes, wire ropes and electrical connections. The aim is to detect possible signs of wear at an early stage and to carry out repairs in good time before a issue or safety risk occurs.

In addition to the annual inspection, ABUS offers a maintenance-friendly service that includes all the important tests and any necessary adjustments or repairs. This way, you can be sure that your ABUS crane will always work reliably and safely.

Our cranes provide more productivity and economy on all levels.

With our cranes, we create up to three working levels that make perfect use of your hall geometry, combine workplaces with each other and thus optimise work processes.

The highest level is made up of our overhead travelling cranes, which transport great and heavy loads of up to 120 t throughout the entire hall area. The ABUS overhead travelling crane impresses with maximum flexibility, as it can be adapted to all building designs through different main girder connection options.

The middle crane level is formed by our single girder wall travelling cranes (up to 5 t) and single girder semi-goliath cranes (up to 10 t). They are especially useful for transporting medium loads between several workplaces along the building wall.

On the lower working level, we recommend our suspended rail systems or our jib cranes as particularly workplace-oriented cranes.

Suspended rail systems with load capacities of up to 2 t are modular, flexible crane systems, which can be ideally adapted to the respective site conditions and performance requirements. Depending on the load, the suspended crane can be moved either manually or via dual speed electric travel drives. When using an HB-System in a transport situation with three levels, the installation of the system will be on our standardised cantilever supports or on a free-standing bespoke steel construction.

Our jib cranes, with a maximum load capacity of 6.3 t, a jib length of up to 10 m (load dependant) and with a rotating jib arm offer you high flexibility with several mounting versions for the floor or wall. A slewing range of up to 360 degrees makes ideal use of space and enables fast and uncomplicated material transport all around the workplace. Depending on the available space, we can install a slewing jib crane as a freestanding pillar jib crane or as a wall-mounted jib crane, which can be mounted directly on existing building supports.

Our lightweight mobile gantry with a load capacity of up to 2 t and a maximum overall height of 5 m is the only mobile crane in our portfolio. This gantry is generally used whenever occasional lifting of loads at multiple workplaces is necessary.

Cranes from ABUS Crane Systems

Fast and uncomplicated installation, ease of initial operation, maintenance and simple servicing distinguish an ABUS crane from the competition. The especially high ‘service friendliness’ of our crane technology has been an essential aspect of the ABUS philosophy from the very beginning. The modularity of our crane systems enables quick repair as well as simple conversion or extension of the systems. All electrical modules are of plug-in type and can, therefore, be easily exchanged or extended. Thus, we guarantee our customers not only fast but also uncomplicated repair work. You will receive complete solutions for your building requirements from ABUS Crane Systems. Our cranes are the optimal means for uncomplicated and efficient transport of tools or heavy loads. You will always receive our lifting equipment with the hoists adapted to the application. Both our electric chain hoists and our electric wire rope hoists are characterized by their small construction heights and offer a wide variety of lifting speeds.

Please do not hesitate to contact us for further information.