JIB CRANES

Working in a team combines the potential of the individual to the overall strength of the company. ABUS slewing jib cranes are powerful and reliable team workers, which make your work easier. With its extensive range of slewing jib cranes, ABUS offers especially flexible and cost-effective material flow solutions all around the workplace.

ABUS slewing jib cranes allow individual adaptation to your application through a choice of hoists, fixing methods and other additional features – all to the highest quality you would expect from ABUS.

They can handle loads up to 6.3 t easily and accurately, all at the push of a button. There are many options available whether the jib cranes stand on their own column or are mounted on the wall or pillar of your building. Whether loading machines, changing heavy tools or lifting workpieces onto work tables - ABUS slewing jib cranes make lifting easier, safer and more economical.

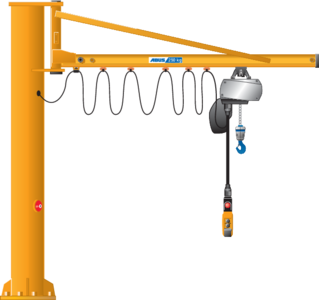

Pillar jib crane LS

The pillar jib crane LS has been designed for freestanding installation on the building floor. This workstation crane provides a slew range of 270° with jib arm lengths of up to 7 m and Safe Working Loads (SWL) of up to 1.0 t. Slewing stops allow you to adapt the slewing range to your individual needs.

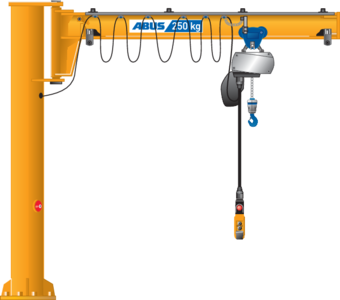

Product details Price enquiryPillar jib crane LSX

The pillar jib crane LSX has been designed for freestanding installation on the building floor. This workstation crane provides a slew range of 270° with jib arm lengths of up to 7 m and Safe Working Loads (SWL) of up to 0.5 t.

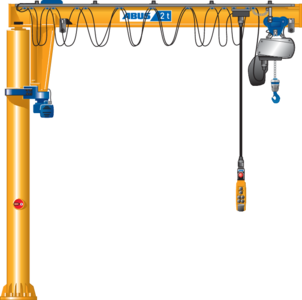

Product details Price enquiryPillar jib crane VS

The pillar jib crane VS has been designed for freestanding installation on the building floor. This workstation crane provides a slew range of 360° with jib arm lengths of up to 10 m and Safe Working Loads (SWL) of up to 6.3 t. The low-built design allows high hook positions for optimal use of the available building space.

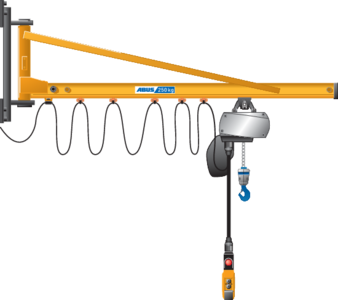

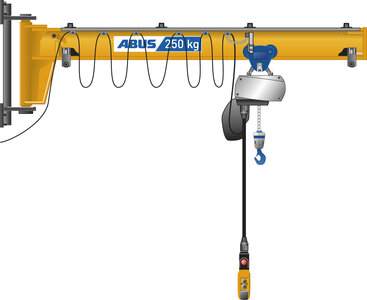

Product details Price enquiryWall jib crane LW

The wall jib crane LW has been designed to be mounted on a wall or column. This workstation crane provides a slew range of 180° with jib arm lengths of up to 7 m and Safe Working Loads (SWL) of up to 1.0 t.

Product details Price enquiryWall jib crane LWX

The wall jib crane LWX has been designed to be mounted on a wall or column. This workstation crane provides a slew range of 180° with jib arm lengths of up to 7 m and Safe Working Loads (SWL) of up to 0.5 t.

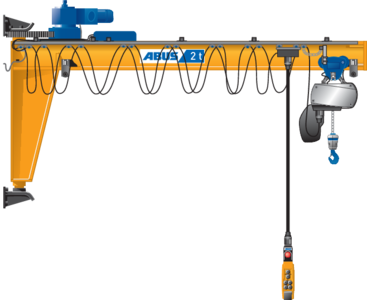

Product details Price enquiryWall jib crane VW

The wall jib crane VW has been designed to be mounted on a wall or column. This workstation crane provides a slew range of 180° with jib arm lengths of up to 10 m and Safe Working Loads (SWL) of up to 5 t. The design of the wall jib crane VW enables the given building dimensions to be used to the fullest extent, so that the transfer of the load is achieved at the highest possible lift height.

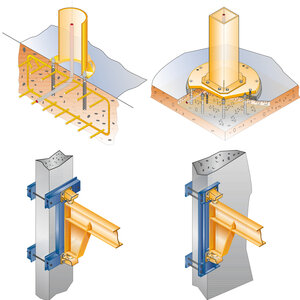

Product details Price enquiryMountings

We can select the right choice for your application from our wide variety of mounting options for our jib cranes.

Product detailsAdditional equipment

Comprehensive additional equipment - customised solutions that really work!

Product detailsFAQ

A wall-mounted jib crane is a special type of crane that is equipped with a long horizontal arm, the jib arm. This jib arm can be used to move loads over long distances and to transport them to places that are difficult to access. Jib cranes are often used in various industrial applications where loads need to be lifted and moved with a wide range and flexibility.

The jib arm is attached to a stable pivot point on a wall bracket, allowing the crane arm to be slewed within a certain swept range. The crane works in combination with lifting equipment such as wire rope or chain hoists to move the load in three dimensions. Depending on your needs, the crane can also be equipped with an electric slewing gear unit to move the crane arm effortlessly.

Whether a floor-mounted jib crane or a wall-mounted jib crane, with or without an electric slewing gear unit, is the best choice can be discussed with your ABUS advisor.

Various mounting options are available for the floor-mounted jib crane, enabling flexible adaptation to the operating conditions. The crane can either be mounted on a foundation provided by the customer, which provides a stable and durable base for the crane, or it is possible to mount an intermediate plate or a dowel plate on a finished concrete floor or concrete ceiling. These solutions ensure that the crane is securely and stably anchored and enable efficient load movement within the operating range.

There are also various mounting options for wall-mounted jib cranes. These cranes can be attached to steel columns, reinforced concrete lintels, steel plates or reinforced concrete walls, depending on the structure and requirements of the building. These types of mounting provide a robust solution for installing the crane, with the crane being attached directly to the existing wall or supporting structure. An ABUS advisor will help to find a suitable solution for every application.

Using a jib crane instead of an overhead travelling crane offers advantages that make it an excellent choice for many industrial applications.

Space optimisation:

Jib cranes allow for a very efficient use of available space, as the rotating jib structure enables the operator to move loads over a large area without having to move the crane itself. This makes them ideal for workplaces with limited space, such as narrow workshops, production facilities or warehouses.

User-friendliness:

Jib cranes are easy to use and often require little effort, which increases ease and efficiency of use. This is particularly advantageous for applications in which small to medium loads have to be moved regularly. The operator can move the load in almost any direction without having to worry about the exact alignment of the crane.

Versatility:

Jib cranes can be installed on a wall or in a free-standing arrangement, offering great flexibility when planning workplaces. They can also be configured with many different combinations of load capacity and jib arm length, making them suitable for a wide range of applications.

Safety:

Jib cranes offer a high level of operational safety. Thanks to their limited radius under overhead travelling cranes, the risk of collisions between cranes or loads with expensive machinery can be reliably ruled out.

You can discuss with an ABUS advisor whether a jib crane offers a good and cost-effective alternative to an overhead travelling crane.

Depending on the model and design, ABUS jib cranes can lift loads of up to 6.3 tonnes at a reach of 5500 mm. The exact load capacity depends on several factors, such as the crane design, the jib arm and the crane's reach.

The radius (i.e. the distance between the crane's pivot point and the load) has a direct influence on the load capacity. As a general rule, the greater the radius, the lower the maximum load capacity of the jib crane. This is due to the fact that the cantilever becomes longer with a greater radius and thus the forces acting on the crane increase. To ensure stability, the load capacity must be reduced accordingly for larger radii. To achieve the maximum radius of 10,000 mm, the maximum load capacity is reduced to 2.5 tonnes.

To determine the maximum load capacity and the appropriate radius, it is therefore important to consider the specific requirements of the working environment. In this context, various model variants and crane configurations are available, which can be adapted depending on the application, to ensure an optimal ratio between load capacity and radius. A competent ABUS advisor will help you find the right crane.