Four ABUS EOT cranes inside a listed building in Sweden

Modern production meets heritage industrial architecture

The company Nohab Industri AB in Trollhättan—north of Gothenburg—can look back on a long company history. Founded in 1847 the then named Trollhättan Mekaniska Verkstad was a machine shop, then in 1916 the name was changed into Nohab Industri AB. Today Nohab is engaged in building components for example for ABB Industrieroboter, for gas turbines for companies such as Siemens and Dresser-Rand, and also for packaging machines while being assisted by modern machinery such as several gantry and bed-type milling machines as well as machining centres. Nohab also builds housing parts for diverse industrial applications. The complete production with a team of about 30 personnel is housed in two buildings built in 1920. These buildings with their delicate timber frame construction and glass cupola roof are now listed buildings.

The old lifting and transportation system is replaced by new ABUS EOT cranes

Not only the production plants date from 1920—the lifting and transportation system had also seen more than half a century go by. Several cranes were from the 1950ies and one self-built crane even dated from 1925! Overhauling and modernising cranes is well possible depending on the technical requirements and the conditions of the main girders and the hoists but in this case the Nohab’s management decided to completely replace the old crane system. A special challenge was for the installation team to get the old cranes off because of the huge weights of the hoists on framework constructions. The old cranes were then taken off the crane tracks by an experienced team once an extensive preliminary examination of the site conditions had taken place and an analysis of the dismantling conditions had been carried out. It had been possible to conserve the existing crane tracks which were now ready for the new cranes to be installed.

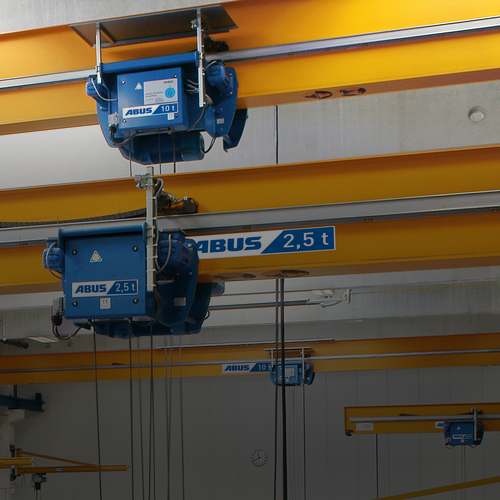

The ABUS solution—modern material handling technology

In total four EOT cranes for both buildings, which have crane tracks with a length of 90 metres installed, were supplied by ABUS Kransystem AB (www.abus-kransystem.se), the Swedish daughter company of ABUS Kransysteme GmbH, via the local agency JJ-Gruppen (www.jjgruppen.se). All EOT cranes have spans of 15 metres and lifting heights of 8 metres. Three single girder cranes ELK have lifting capacities of 10 tonnes each, the double girder crane ZLK has a SWL of 20 tonnes. The single girder cranes have been fitted with electric wire rope hoists, model E, the most common hoist used in the lifting range up to 16 tonnes. The double girder crane has been fitted with a double-rail hoist DA whose stooled-down design makes it possible to use the available space to an optimum. All cranes transport work pieces to the respective workstations. During every phase of this project starting with the design of the cranes, the dismantling of the old cranes, the installation of the new cranes, and the commissioning the company Nohab had a competent partner at its side through the ABUS service station nearby. Nohab also signed an ABUS service contract for regular service and maintenance of the cranes.