Five ABUS EOT cranes at a manufacturer’s of wood processing machinery

There is one detail—nearly overlooked—in the world of the ever growing flow of commodities and faster spinning logistics, a little detail without which the movement of goods would not be quite so smooth: the standard pallet. The standard pallet makes it possible to transport all sorts of goods and merchandise. Pallets come in standardised dimensions similar to containers and are easy to transport by industrial trucks such as forklift trucks.

Wood processing machinery

At a first glance the pallet appears to be a mass product easy to produce. However, the manufacturing process is fully automated and divided into different phases. Each phase requires its own specialised machinery: to hammer in the nails, to chamfer and to cut the planks, as well as for signage to name but a few. MECANICA CAPE, S.L. (www.cape.es) is a family owned company in Barcelona founded in 1967 who have come to specialise in this sector of machine construction due to the fact that this type of equipment was sought after when the market for pallets started to emerge and to grow in the 1970ies. Thanks to their knowledge in this particular area CAPE were the first manufacturer of machinery for pallet construction in Spain, now they are counted among the world market leaders exporting into well over 45 countries. A team of engineers focus on innovation and the development of individual solutions for customers and their needs. These engineers are not only occupied with machinery for pallet production but also with the production of wood stacking machinery and machinery for the production of reels (huge reels for cables).

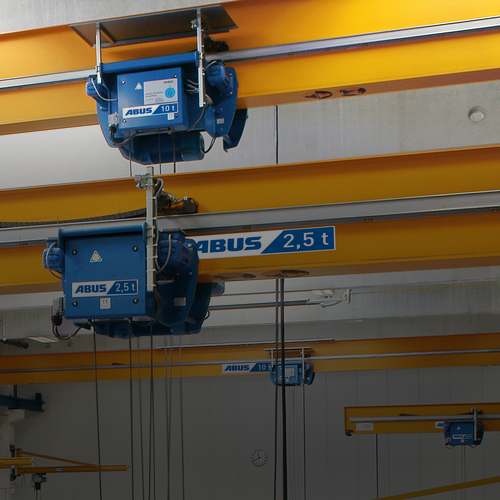

ABUS EOT cranes

For more than a decade the company CAPE in its modern production plants has relied on ABUS products to ensure a fast and efficient flow of production. The first EOT cranes were installed in 2000: two cranes of the ZLK type (double girder cranes) with spans of 18,700 mm and lifting capacities of 6.3 tonnes each. In an expansion project in 2011 a further three EOT cranes of the ELK type (single girder cranes with welded box girders) were installed with lifting capacities of 6.3 tonnes and spans between 9,600 and 19,600 mm. The monorail hoists in version GM2000 E with their compact design and favourable dimensions beautifully adapt to the very low building and ensure a maximum lifting height.

ABUS Grúas’ technical solution

CAPE relied on ABUS Grúas (www.abusgruas.es), the Spanish daughter company of ABUS Kransysteme GmbH, right from the first EOT crane project on. The team of engineers and installers of ABUS Grúas were faced with diverse challenges during this project: as the industrial plants were relatively old the existing concrete pillars did not have any brackets. ABUS worked together with CAPE’s engineers to design the necessary supports for the crane tracks. Then once the EOT cranes had been delivered to their destination inside CAPE’s plants part of the roof had to be dismantled to allow the mobile crane enough working space to install the cranes. However, the erecting engineers mastered the task with much precision and circumspection. The services offered by ABUS Grúas were not limited to technical assistance, delivery, and installation of the cranes: CAPE signed a service contract with ABUS Grúas aiming at proactive maintenance in order to ensure the perfect functioning of the crane systems.