Walter Watson fits out €50 million global headquarters for COMBILIFT with ABUS cranes

Northern Irish structural steel fabricator and crane supplier Walter Watson Ltd (www.walter-watson.co.uk) have supplied ABUS Cranes to one of the largest manufacturing facilities under one roof in the Republic of Ireland.

Irish forklift manufacturer Combilift (https://combilift.com/en/) who opened their new €50 million Global Headquarters and manufacturing facility in Monaghan selected Walter Watson Ltd to supply the cranes used for both the building of and operation of its new facility.

The project, the largest undertaken by the Northern Ireland based company, was completed prior to the official opening of the facility in 2018 by An Taoiseach Leo Varadkar and Heather Humphreys TD, Irish Minister for Business, Enterprise and Innovation.

Combilift manufacture multi-directional, articulated Forklifts and Straddle Carriers for container and specialist load-handling applications. The 46,500 square metre facility is the centre of the company’s global operations, with 98% of its production exported to 85 markets around the world.

Established in 1998, Combilift is a long-time customer of Walter Watson Ltd, having purchased a number of ABUS cranes for their previous facility, also in Monaghan.

“The excellent service record of the cranes meant that when it came to the fit out of the new purpose facility Walter Watson were a natural first choice”, according to a Combilift spokesperson. “By supplying both the building and crane package, Walter Watson were able to offer phased crane deliveries during the build process which was essential to the tight time frame Combilift required.”

Using market-leading ABUS crane components supplied by ABUS’ UK based subsidiary – ABUS Crane Systems Ltd. (www.abuscranes.co.uk), Walter Watson completed the crane with crane beams manufactured in Castlewellan.

Walter Watson produced 61 overhead cranes from ABUS kits, almost half of which are ELV type single girder cranes where the main girder is made from a rolled section beam.

Where the single girder cranes required larger spans, these cranes were built with box section beams fabricated by Watsons.

12 ZLK type double girder overhead cranes and 4 semi-goliath cranes were also manufactured and supplied, all with dependable ABUS wire rope hoists and end carriages. The cranes, some with ABURemote radio remote controls, offer Safe Working Loads ranging between 5 and 25 tonnes.

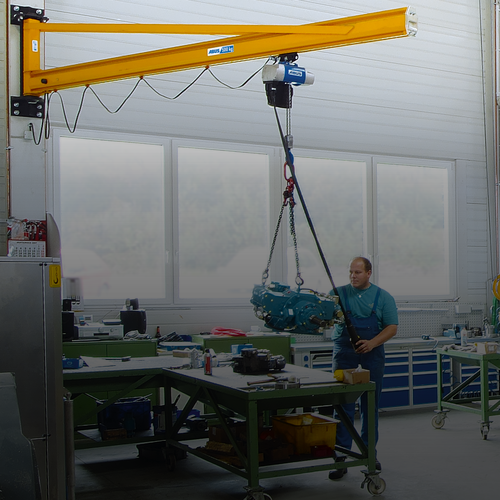

32 jib cranes were also supplied, the majority of which were mounted on the factory floor via anchor bolts set into a concrete foundation. Overbraced ABUS LS jib cranes with a Safe Working Load of 1000 kg were employed in lighter weight applications, while the heavier duty underbraced ABUS VS type jib crane was chosen for applications where a Safe Working Load of 2 tonnes was required.

Eight of the ABUS overbraced LW wall-mounted jib cranes were also fitted to columns within the Combilift facility to provide a localised swept radius lifting solution.

Combilift also purchased 4 ABUS EHB light crane systems, each of which has more than one crane bridge with an ABUS chain hoist, to provide a flexible lifting arrangement which is light enough to be moved around manually. 4 ABUS monorail hoists were also supplied for specific linear point-to-point lift and shift applications.

Walter Watson Crane Division Manager Harry Palmer said that they were delighted to be selected for what was their largest project to date. “This fit-out showcases our complete product range.” He added: “It is terrific to see a local company enjoying global success and in turn making such a substantial investment back into the local economy in this region. The thorough planning and meticulous attention that we pay to the manufacture of our products combined with the high quality ABUS components means that we are supporting Combilift to efficiently handle and store their materials. This is in turn allows Combilift to offer customers cost saving handling and storing solutions.”