FIVE ABUS EOT CRANES AT KFK TEHNIKA, a Croatian manufacturer of aluminium and glass facades

Today’s business objects with their modern design and superior quality are produced by specialised companies. One of these companies is KFK Tehnika Ltd. (www.kfk.hr): their experience contributes to the construction of many famous buildings in Croatia, in Europe, and even worldwide. KFK Tehnika’s quality, capacity, and fast implementation—from the planning to the full completion of the project—have satisfied the high demands of domestic and foreign investors.

The company was founded in 1997 and started with 6 employees. Today KFK Tehnika is the leader in the manufacturing of aluminium and glass facades in the central-eastern part of Europe with more than 200 employees. In addition to the headquarters in Zagreb KFK Tehnika also have project offices in Slovenia, in Bosnia and Herzegovina, and in Bulgaria while the production plant is located in Zagreb, Croatia.

The long list of completed projects among which are numerous Croatian ones also includes projects built across Europe and even further afield. For example, the Museum of Arts & Design in New York, the shopping centre Westfield in London, the airport in Frankfurt, the Palazzo Geretta in Lugano, the Raiffeisen Tower in Vienna, and many others.

The vision of KFK Tehnika is to contribute to the development of new systems, to set new standards in terms of quality, functionality and design of structures and glass facades, and to be always one step ahead. The use of new environmentally friendly materials in accordance with the latest European standards leaves room for significant energy savings, helps to preserve the environment, and also contributes to the improvement of the living conditions of future generations.

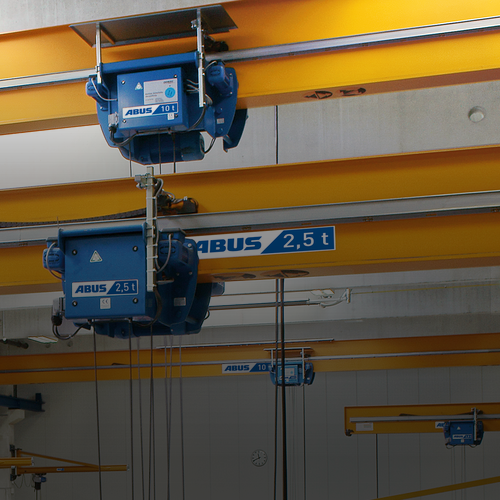

KFK Tehnika owns over 20,000 m² of production facility, equipped with the latest machining centres as well as several ABUS EOT cranes and material handling solutions based on ABUS HB components. With about 200 employees in the group and with the tendency to further expansion and development, KFK Tehnika continues to invest in production facilities, modern technologies, and the training of staff.

As a logical consequence of that strategy, KFK Tehnika decided in 2014 to invest in the construction of three additional buildings, each about 300 m long, with the total area gained amounting to about 15,000 m². The buildings vividly demonstrate the latest technical and aesthetic achievements in the application of glass facades. One part of the area will serve as a warehouse while most of the space will be used for production. Manufacturing has a modern concept, where special attention is paid to material handling.

Five ABUS EOT cranes were installed in the production area, with load capacities of 5 tonnes each, and spans of 19.2 metres. Three of the EOTs are installed on the same crane runway which is 300 meters long. Each of them will work in its own space, but in case of need each of them can help the neighbouring crane in the event of a rush hour. Therefore, the long travel speed is specially designed for working on the long crane runway and each of the cranes is equipped with photo-electric barriers to prevent collisions. A special request of the investor was the colour of the cranes: all machines must be in white, as well as other devices and steel constructions which gives the facility a futuristic look. Cranes were delivered by ABUS’s local partner in the Croatian market, the company DEMATEH Ltd. (www.demateh.hr).

The main task of the five single girder cranes of the ELK type—they are all equipped with a monorail wire rope hoist each—is to handle the incoming material and to assist in the production. The use of these 5-tonne cranes will allow KFK Tehnika to produce more complex and advanced facade systems which will result in further strengthening their market position. It is quite interesting to note that this delivery of five EOT cranes is only the first stage in the completion of their material handling system. In the future, there will be an installation of two additional EOT cranes and also several HB cranes equipped with manipulators for handling glass surfaces will be needed.